About Sholphin India

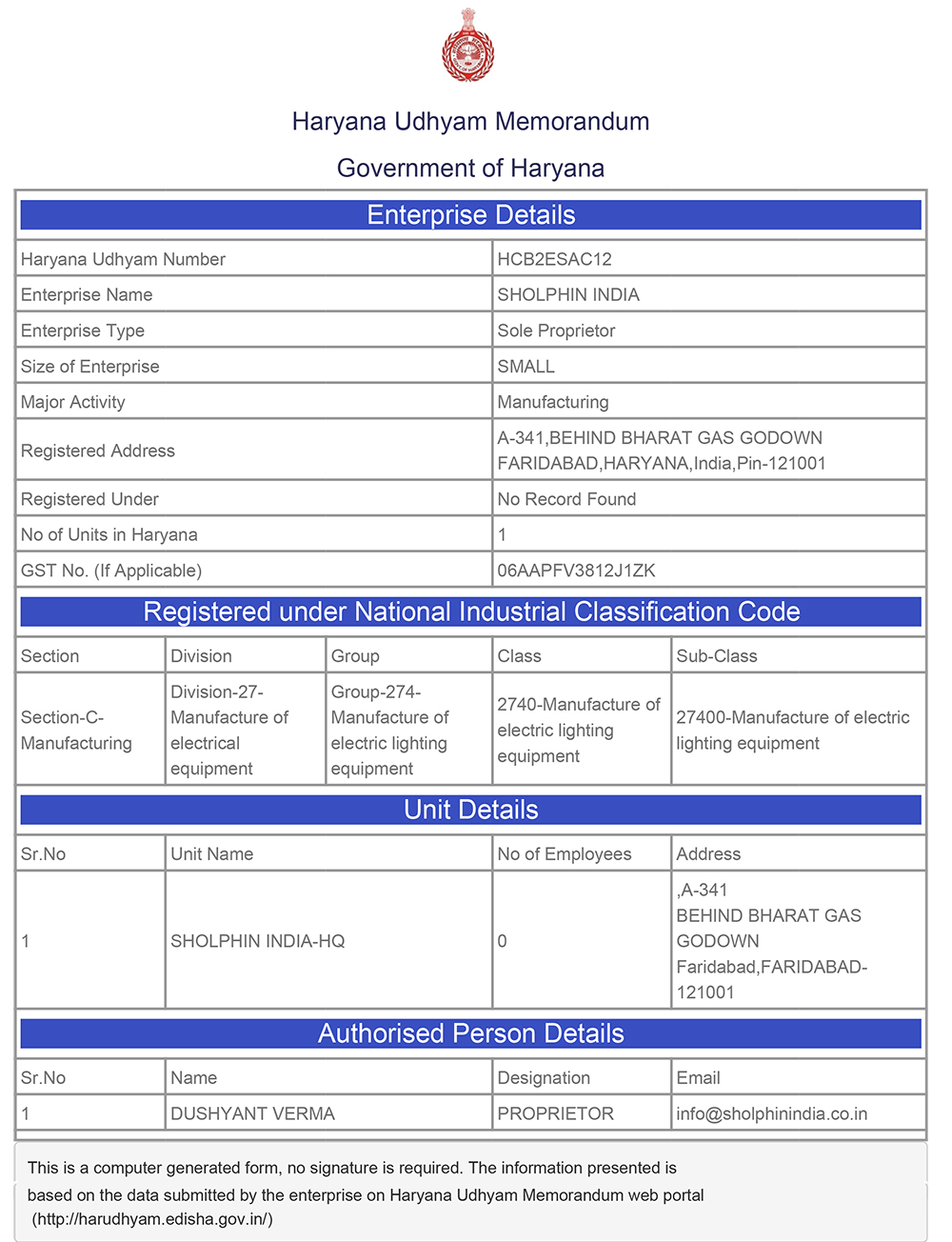

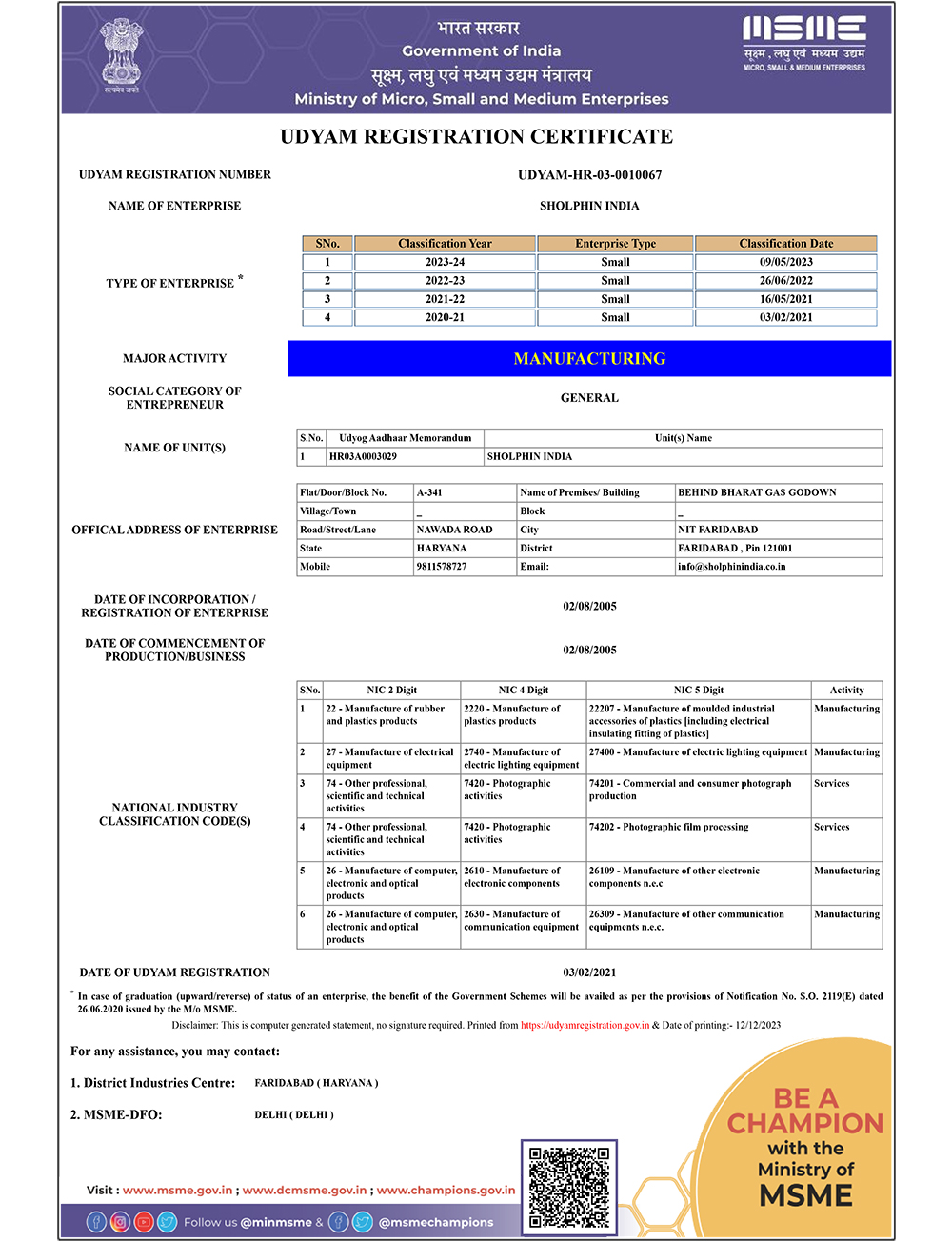

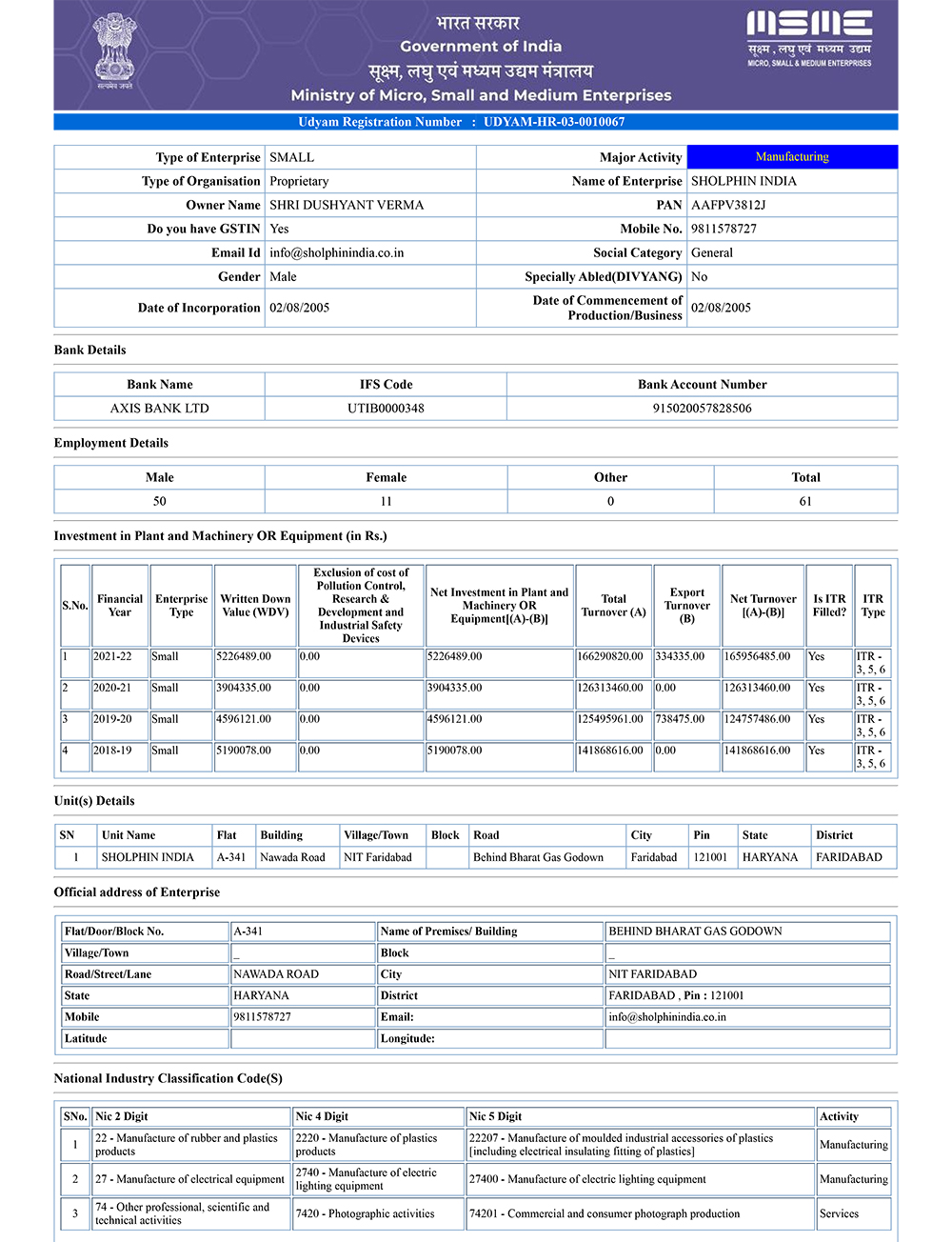

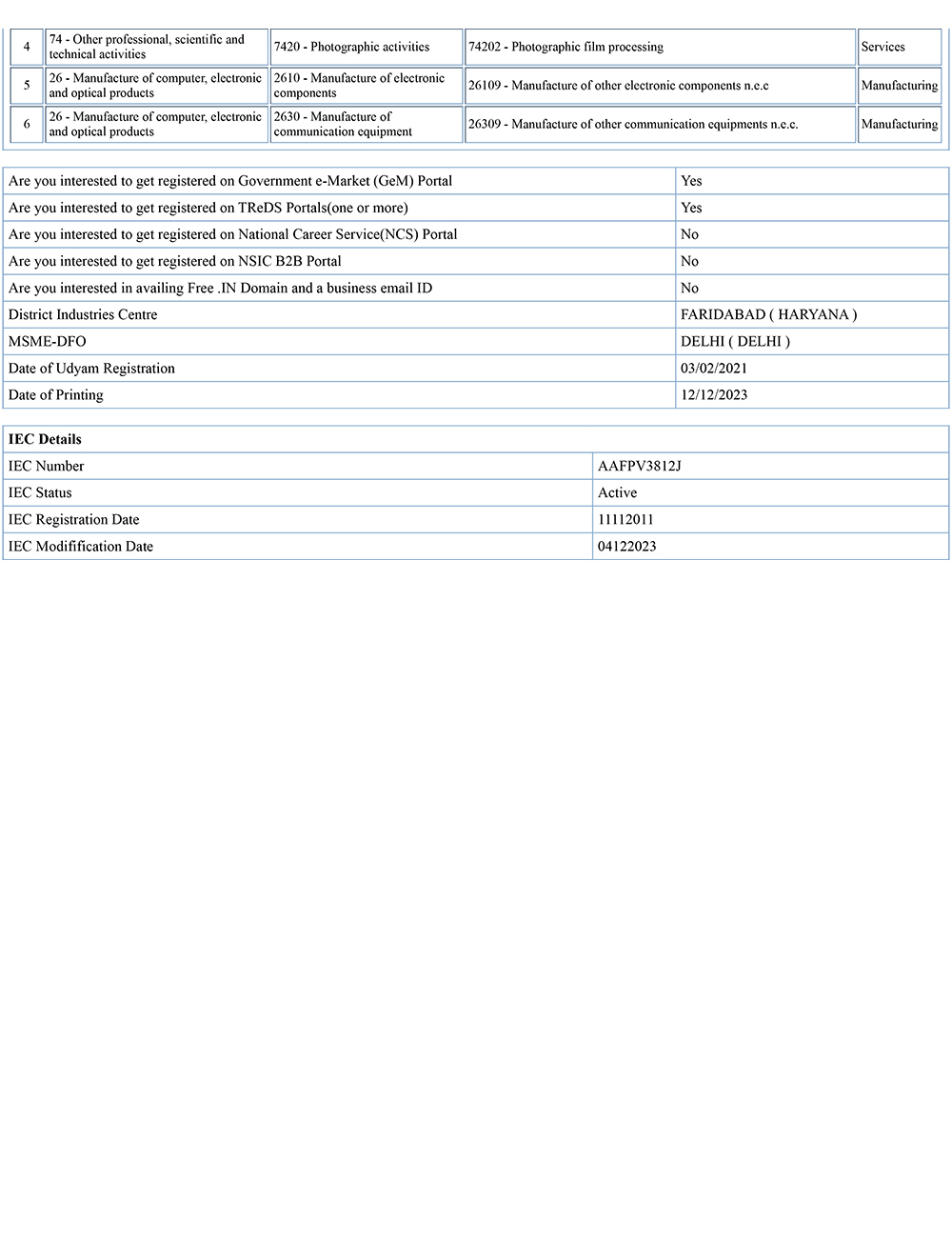

Established in the year 1994, Sholphin India has grown from a proprietorship firm to a Pvt Ltd. firm under the name of Sholphin Solutions Pvt. Ltd.

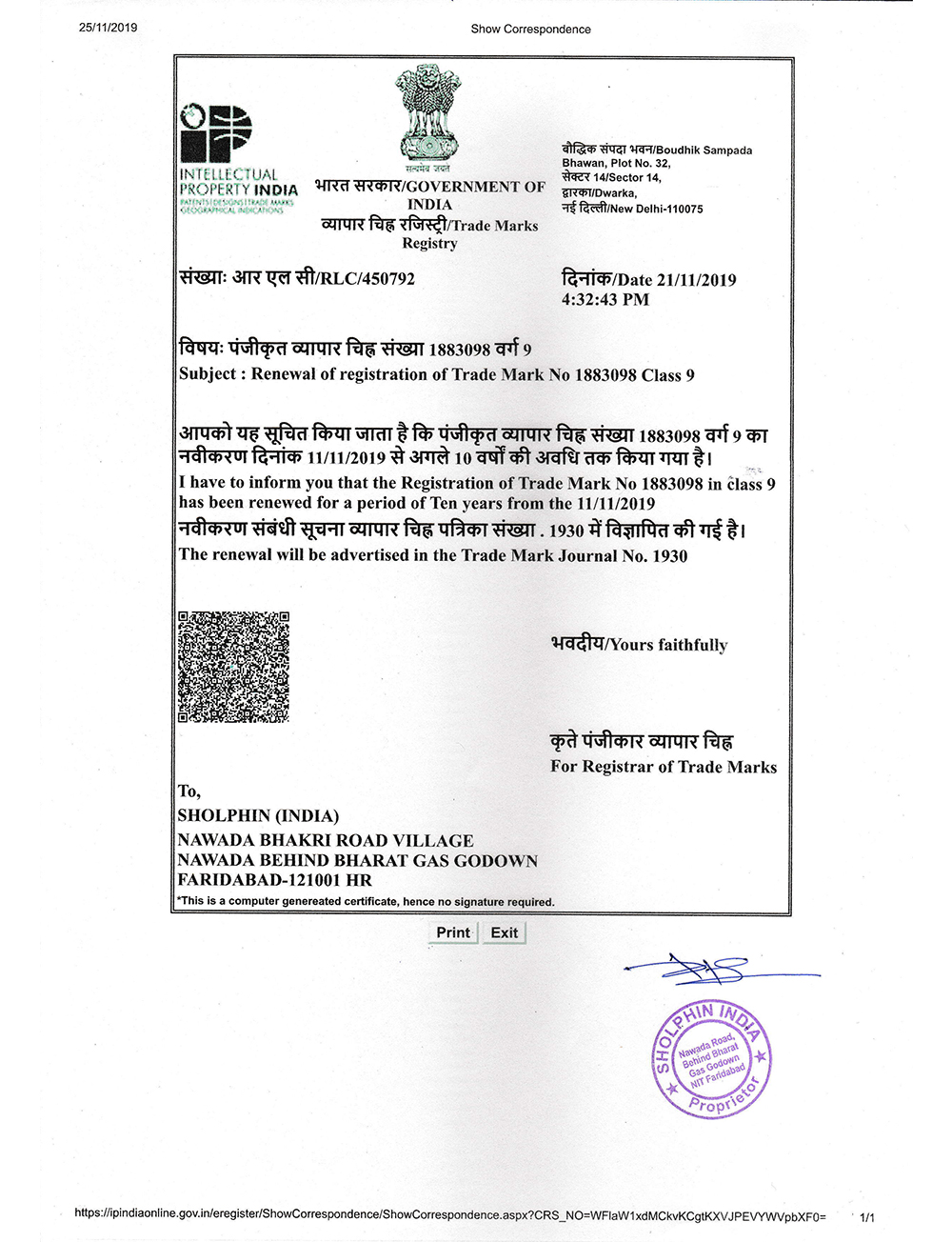

We have been supplying visual and audio warning signals to emergency services for over the last two decades and are the first ones to replace halogen bulbs with LEDs in the Indian market.

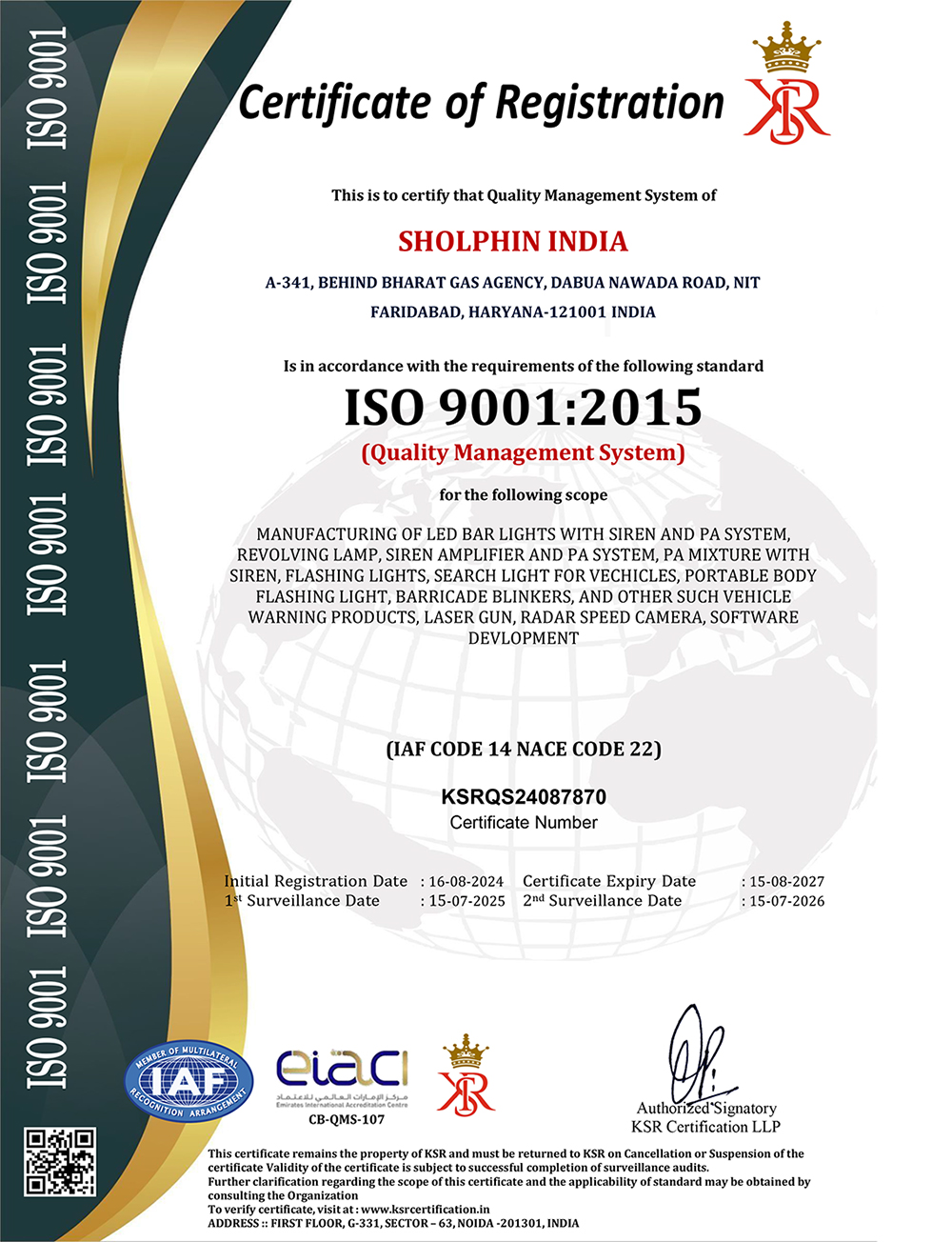

Our Company has two Manufacturing Plants-Unit 1 situated near Nawada Industrial Area, Faridabad and Unit 2 in ‘Industrial Model Town’ Faridabad. We have in-house Injection molding machines, Sheet metal workshops & Paint shop where all the parts go through strict quality inspection at multiple stages. All our Light Bar models, Siren Amplifiers & Beacons are successfully tested by the Automotive Research Association of India (ARAI) & International Centre for Automotive Technology (ICAT), According to the international specification.

We have been in the business of manufacturing emergency bar lights, searchlights, Siren & amplifiers for OEMS & Pan-India covering both Govt. and the Public Sector in India. Over the years we have built a flexible production system capable of building a variety of products to fit the expansive application needs of our growing customer base.

Some of our achievements over the past few years are

-We had the honor of designing HERO HONDA KARIZMA bikes for the COMMONWEALTH GAMES that were accompanied by eminent personalities of India.

-We have done DIAL 112 projects for the U.P police, Delhi Police, Haryana police, and Madhya Pradesh Police.

-We have also received appreciation letters from OEMs like Force motors Ltd. and Pinnacle Industries Ltd. for uninterrupted supplies during the tough COVID times.

We have a dedicated technical team who are available to deal efficiently with any inquiry within the quickest possible time frame. Our team is well known within the industry and ‘goes the extra mile to assist customers in receiving the best possible service.